Technology

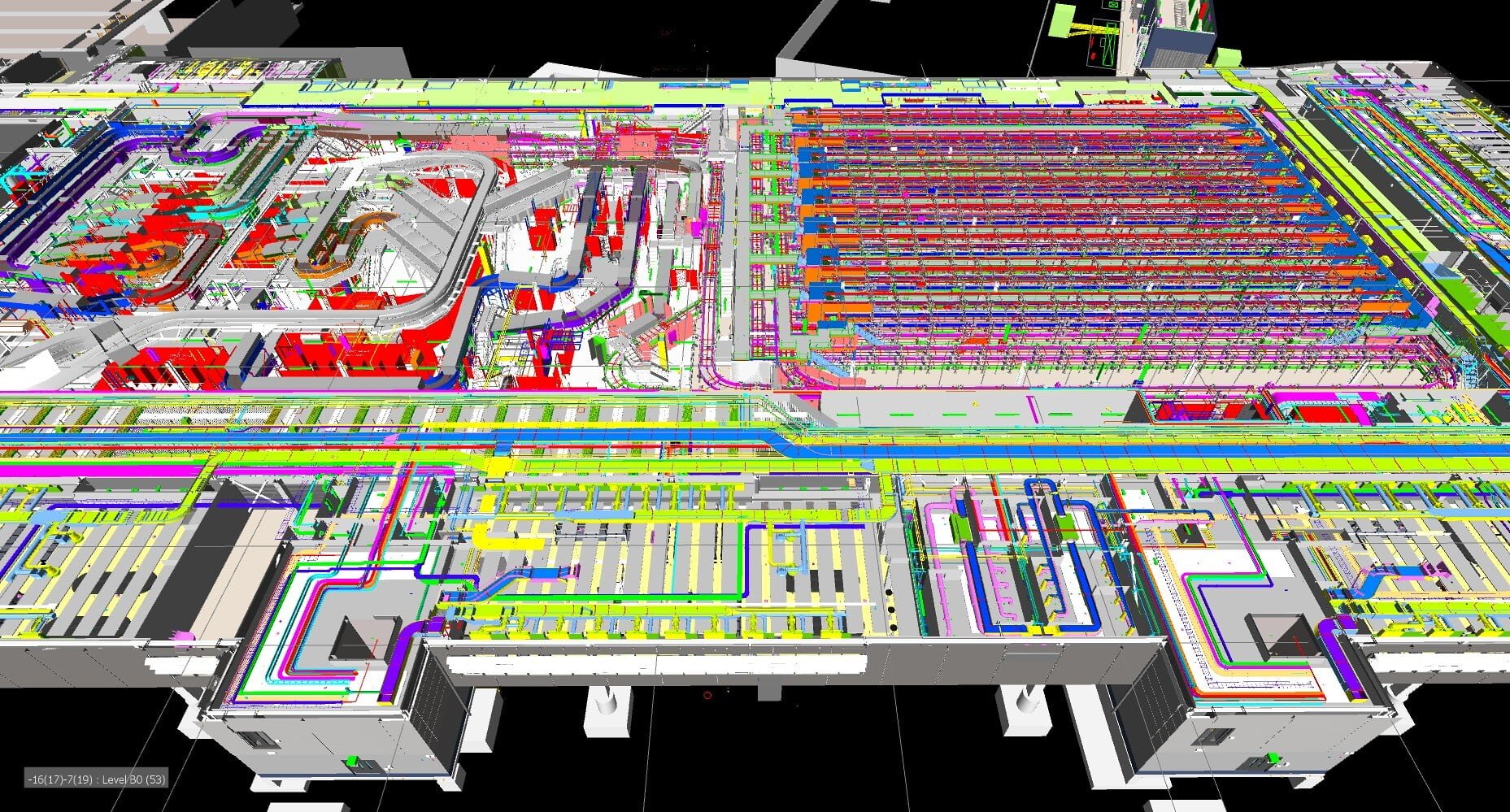

GeoInstinct leverage the latest digital technologies and toolsets to provide integrated design and detailing services. Our optimised processes and workflows have been aligned to the Design for ‘Off-site’ Manufacture and Site Assembly (DfMA).

This approach enables a standardised digital design solution which supports the modularisation and mass production of pre-cast concrete and hybrid structures, timber frame, metal frame, façades in metal cladding, stone, and also modular Building Services, cabling and HVAC systems.

Importance

Adopting digital toolsets and workflows has enabled us to change the mind-set of the more traditional and bespoke approach. Our early involvement in the design process allows time to leverage the benefits of design and manufacture standardisation. Applying digital technologies which allow us to analyse and optimise component form and their configurations we are able to offer the following benefits:

- Initial feasibility studies

- Off-site manufacturing and pre-stressed concrete construction advice

- Reduced design lead times

- Improved quality, seeing a reduction in overall project waste

- De-risking of delivery programme

- Optimisation and standardisation of components, seeing a reduction in both the manufacture and erection phase durations

- Use of our expertise as temporary works designers

Benefits

Our approach brings significant benefits, including:

- Controlled factory conditions

- Improved precision and quality

- Optimised site transport and logistics

- Safer and cleaner working conditions

- Avoidance of poor workmanship

- Greater speed and co-ordination of on-site programme

- Fewer on-site weather delays